Description

Product details

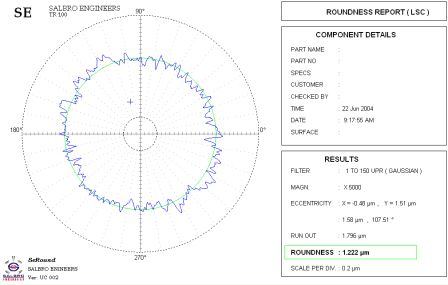

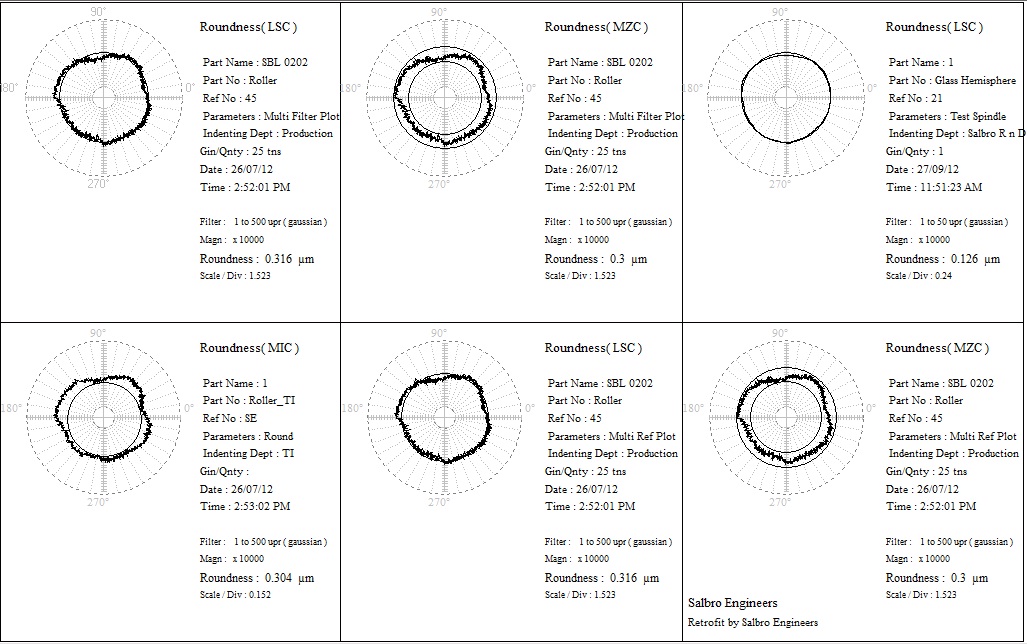

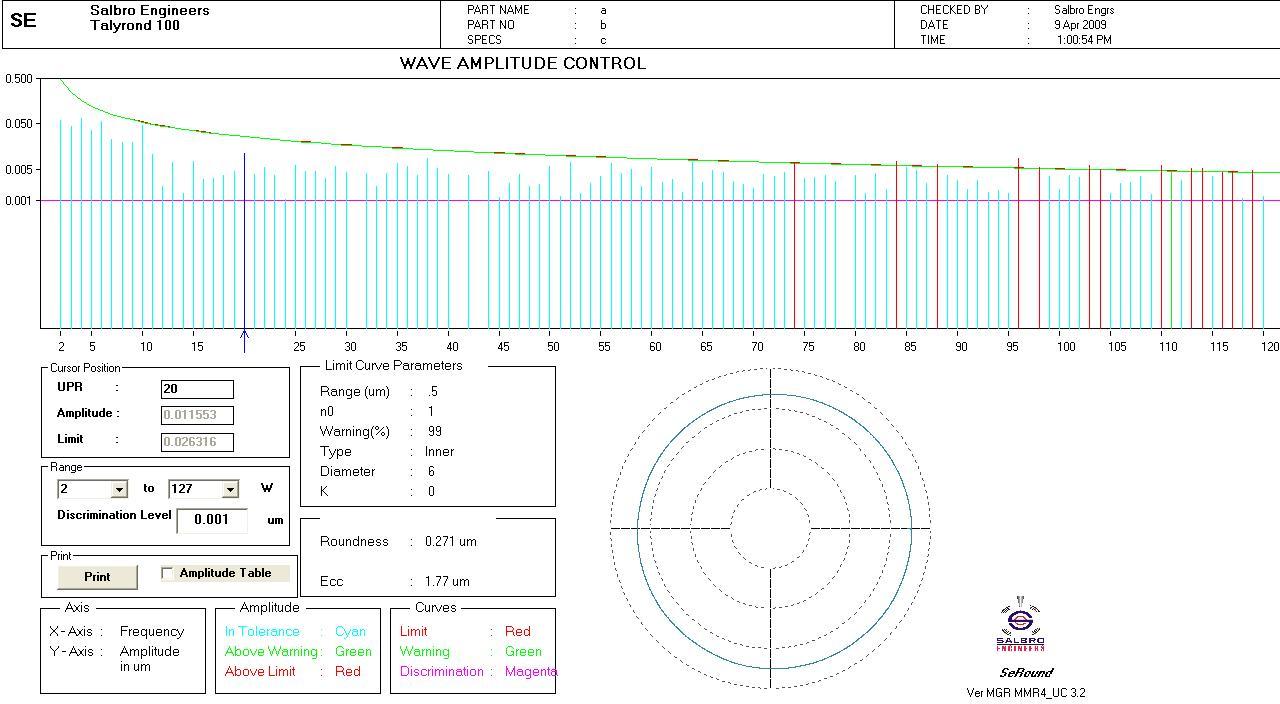

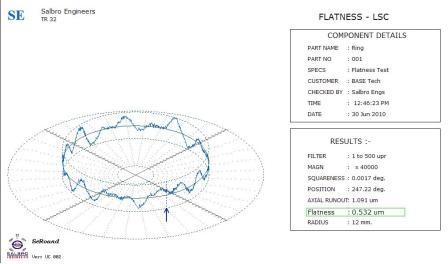

PC Retrofit Roundness Measuring Machine : Hommel 1000 Pls Note : Machine pictures Displayed are Proprietary products of Respective Manufacturers. Pictures of machines are used to show compatibility of our Retrofit package to them. • Air-bearing rotary table: Ø 150mm expandable. • Rotation speed: 5rpm • Centering range: 3mm • Leveling range: ± 0,6 mm • Max work piece diameter: 500 mm • Max work piece weight: 20 Kg • Spindle rotation error: 0,04 μm • Stylus resolution: 0,01 - 0,05 μm • Stylus measuring range: 400 - 600 μm • Polar filter: undulation/revolution: 1÷15, 1÷50, 1÷500, 15÷500 • Linear Filter cut-off: 0,25 - 0,8 - 2,5 - 8 mm • Parameters: Roundness, Concentricity, Flatness. Squareness, Coaxiality, Run-out. • The Hommel 1000 instrument has a rotating spindle with an numatic bearing. Whilst the Hommel 1000 maintains a high level of measurement accuracy and performance reliability, it represents only a minimum of capital investment. • The optimal measuring speed is 5 rpm. Other speeds would reduce the transmission characteristics of the measurement chain. In this model the arm is moved manually and it allows to measure at 250 mm in height from table surface. • SeRound the Software Retrofit for Hommel 1000 is accurate, user friendly, robust and is performance driven. It is developed in-House at Salbro Engineers and provides a through interactive user interface between the user and the Instrument with the help of the Electronic Interface unit also developed in-House at Salbro Engineers All Integrated to make one precise instrument to detect the following • Parameters: Roundness, Concentricity, Flatness. Squareness, Coaxiality Run-out.. Data acquisition, profile filtering, evaluation of the roundness parameters and graphical output of the results as well as for the instrument control (like Starting and Stopping the motor and selection of the amplifier range) has been realized by SeRound. The cycle of measure guides the operator in the operations of table centering and leveling and subsequently in the acquisition of the profile. Besides the default cycles of measure it is also possible to make calculations on the previously acquired profiles; moreover it is possible to plan the cycle of acquisitions. This is very useful especially when you have to measure many similar work pieces, with the same parameters and you need to enhance the measuring speed. SeRound allows you to choose the method of calculation to perform the measurement and to elaborate the results. For the Roundness: circumference of the minimum squares, circumference of minimum zone, minimum circumscribed circumference, maximum subscribed circumference. For the Flatness: plan of the minimum squares, plan of the minimum zone, minimum superior plan and maximum inferior plan. One can even omit unwanted data not required to be analyzed. SeRound’s Setup and Measure window provides a tool to the user to center the jobs quite accurately and quickly thus saving on time and improving productivity. Hommel 1000 with SeRound Analysis software comes with 12 months warranty period