INR 1

INR 1

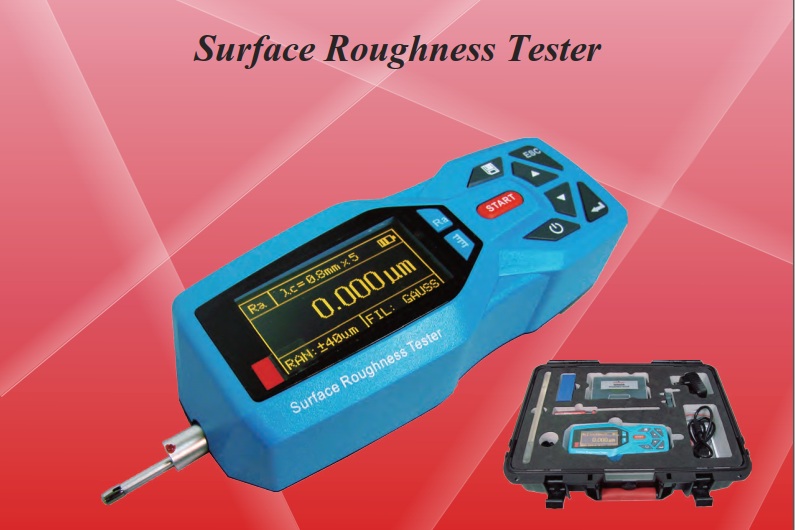

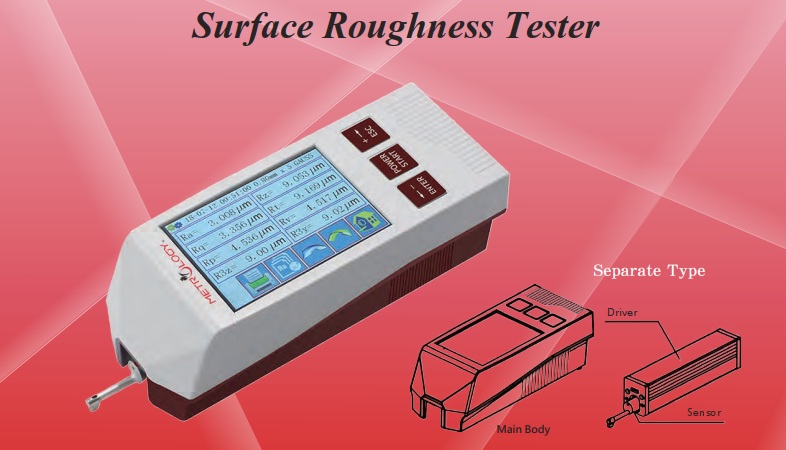

Measure Components |Measure Balls for Roughness |Measure Components for Roughness |Measurement Service |Ra |Rz |Roughness Parameteres |Roughness Measurement |Waviness Analysis |Waviness Measurement |Roller Camber Measurement |Roller Camber Analysis program |Roller Camber Assesment |election |Voting Machine |Digital Voting |Candidates |electronic voting |Electronic Voting Machine |EVM |Vote |Election voting Machine |Co-Op Bank Election |Roughnesss |Surface Roughness |Palmtop Roughness |Surface Metrology |Roughness Tester |surface analysis |Portable Roughness Tester |WARPsurf |roughness parameters |Roughness |Waviness |Dominant waviness |Material ratio curve (bearing) |height amplitude distribution |roughness average |roundness |Concentricity |Parallelism |Cylindricity |Diameter |Perpendicularity |Thickness variation |New Roundness and Cylindricity |roundness tester |Roundness Measuring |roundness measurement |Cylindricity measurement |Straightness |bearing ratio curve |ra |unfiltered profile |Gaussian Filter |2CR filter |Digital filters |Machine control |Pre-owned Machines |Retrofit Pakage |Surface Roughness & Waviness Retrofit |surface roughness retrofit |Analysis software |Analysis |Roughness Average |Retrofit |Bearing |Radial Play |Radial |Embedded |ADC |Plunger Probe |Bearing Radial Clearance |Data Logger System |Embedded system |Embedded coding |Lan Remote Connect |Rollers |Rings |Bearings |Camber |Measurement Services |Calibration |Contour Measurement |Contour Machine Calibration |Calibrate |CAD program |CAD functions |Roundness Teste Retrofit Package |Laboratary Roundness Tester |Upgraded Software |Flatness |Relative Eccentricity |eccentricity |squareness |Velocity Analysis |Harmonics |Axial Runout |Radial Runout |Rt |Balls |Portable |Contour |Talysurf5 |120mm Traverse |Retrofitted machines |SeSurf Retrofit Package |On Sale |Surface Finish |Roughness Mean |large Size Bearings measurement |Form Measurement |turbines measurement |compressors measurement |Roundness |Cylindricity with Roundness |coaxiality |spherocity |SKF Waviness Analysis |total run out |run-out |Portable Roughness |Talysurf4 |Transperant, Reliable, Robust |Linear Graph |FFT algorithum |LSC |MIC |MCC |MZC |Specimen hemisphere |Guizzo specimen |Specimen cylinder |calibrate sensitivity |Glass Hemisphere |Master Cylinder |Soccer |Trainer |Goal Keeper Trainer |Football Trainer machine |football |Train |linearity |cylindricity |conicity |concentricity |parallelism |thickness variation |Labortary Roundness Tester |contour |Profile Studio software |Election |VVPAT |EVM Rentals |EVM for Hire |EVM on Rent |Soccer Trainer |unmanned system |football practi |Surface Parallelism |harmonics |data accusition |Best Fit Curve |Best Fit Line |Slope Removal |Profilometers |Automatic CNC positioning |Automatic CNC measuring |Portable Surface Roughness Tester |Transparent Results |Electronic Voting |vote |multiple voting |non tamperable |EVM manufacturer |Election voting System |Voting Systems |Flatnesss |Parking |Parking Solutions |Parking management |Unmanned Parking |parking lot |Parking assistance |Voting |Voting Center |Voting Booth |Multiple Voting |Talyrond 252 |SeRound |ISO standards |ISO 13565-1 |Radial Clearance |Brearing Play |Datalogger |Log Data |Multiple Category Voting |large Size Bearings |large size bearings |Cylindricity With Roundness |Multi Profile Plot |Wave Amplitude Control |camber |Height